- Home

- froth-pak-foam-system

- Froth-Pak™ 200 Foam System

Spray Foam Insulation & Sealant Kit

Froth-Pak™ 200 Foam System

- Polyurethane spray foam insulates cavities and air-seals joints and penetrations

- Class-A Fire Rated, two-component, quick-cure formulation

- Froth-Pak™ 200 Insulation and Sealant covers 200 square feet at 1” thickness

- Provides an R-value of 6.2 at 1inch thick and 12.2 at 2 inches thick

- 30-second cure time and 1-hour room reentry helps saves time on the jobsite

-

Product Details

Froth-Pak™ Foam System is the all-in-one, self-contained, disposable kit for professional contractors to insulate walls and cavities and seal gaps and penetrations quickly and efficiently.

-

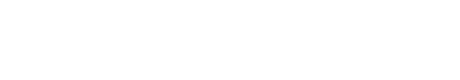

What’s In the Box?

-

More Product Details

Froth-Pak™ Insulation and Sealant Foam System is a Class-A Fire-Rated, 2-component, quick-cure polyurethane foam that effectively fills cavities, penetrations, and cracks in rim joists, roof-wall junctures, and around pipes and ducts up to 2 inches thick. Froth-Pak™ is a chemically cured foam that dispenses, expands, and becomes tack-free in seconds, saving pros time on the jobsite.

The low Global Warming Potential (GWP) formula contains no ozone-depleting chemicals or HFCs, while still maintaining the performance attributes that professional contractors expect. The formulation features a fast cure time and high closed-cell content. The Insta-Flo™ dispenser offers minimal overspray while the patented nozzle and flexible hose provides easy and ergonomic dispensing. This is designed to offer unsurpassed performance and ease of use, all while maintaining Froth-Pak™ Spray Foam’s commitments to sustainability.

-

Features & Benefits

- Two-component, quick-cure polyurethane foam system with all-in-one Class-A Fire Rated formulation, used to both insulate cavities and create a continuous air-barrier by sealing penetrations and joints

- Yields approximately 200 square feet at a 1-inch thickness

- Provides an R-value of 6.2 per inch and is Class-A Fire Rated up to 2 inches thick (12.2 R-value)

- Froth-Pak™ can be applied up to 2 inches thick in one pass. Additionally, a 30-second cure time and 1-hour re-entry with proper ventilation results in time-efficient installation

- Anti-crossover nozzles ensure consistent flow rate, on-ratio application, minimal clogs, and complete dispensing of the product, while the flexible hose assembly means easy movement and ergonomic dispensing

- Applications include roof and wall junctures, walls and attics, flash-and-batt applications, crawlspaces, basements, as well as electrical, mechanical and plumbing penetrations in the building envelope, and HVAC joints. The Froth-Pak™ 630 Foam System is particularly well-suited for bigger applications such as larger renovation projects or cold storage insulation

- Bonds to wood, rigid foam, masonry, metal, drywall, and most construction materials

- Closed Cell Formulation; helps reduce the potential for moisture, mold, mildew, allergens, and rot

- ENERGY STAR certified, GreenCircle certified, LEED V4 compliant, ICC Listed. Contains no ozone-depleting chemicals or HFCs, providing peace of mind on the job site

- Each self-contained kit contains an ISO (A) cylinder, a polyol (B) cylinder, an Insta-Flo™ dispensing spray gun, 8 cone spray nozzles, 4 fan spray nozzles, 1 wrench (5/8 in.), 1 petroleum jelly packet, and a [9-foot/15-foot] gun hose assembly

- Shelf-life of 24 months from the date of manufacture. Reusable for 30 days after opening when following all manufacturer’s instructions, helping to ensure entire kit can be utilized

1The theoretical yield has become an industry standard for identifying certain sizes of two-component kits. Theoretical yield calculations are performed in laboratory conditions, without taking into account the loss of blowing agent or the variations in application methods and types.

2R-value per inch: ft²•h•°F/Btu; aged LTTR measured at 2-in. thick.

-

Helpful Tips

- Avoid exposing cured foam to temperatures above 240°F.

- Tubing inside the tank can become damaged if shaken too hard.

- If applied outdoors, be sure to paint or cover foam to prevent discoloration and UV damage.

- Always refer to the installation guide for safe usage and local building codes prior to application.

- For best results, the tank contents should be at 75°F (24°C) or warmer. Ambient and surface temperatures should be 65°F or above.

- The temperature indicator – not available on Froth-Pak™ 650 kits – on the side of the tank shows the temperature of the contents of the tank, not the ambient air temperature.

- Froth-Pak™ Foam can be applied effectively in cooler air temperatures or on cooler work surfaces provided the kit contents are at least 75°F (24°C). (See user manual, Section 4.3 - Cold weather spray guidance)

- If hoses are not already attached, use the wrench provided in the Gun / Hose Assembly Kit or your own 5/8” wrench to tighten the hose assemblies for both “A” and “B” valves until both are tight.

- Apply petroleum jelly to the inside surfaces of the face of the gun

- Do not attempt to reuse the nozzle if the spray has stopped for more than 30 seconds (or more than 15 seconds for the FROTH-PAK™ High-Density product). Restart times are impacted by temperature. (See section 3.2 in user manual)

- Do not reuse a cured or partially cured nozzle. This may cause foam to crossover in the gun, rendering it unusable.

- If A:B ratio appears wrong, check face of the gun to ensure the ports are clear of cured material (you should be able to see the silver finish of the aluminum spool in the ports). Purge foam through gun for a few seconds without a nozzle. Replace nozzle and try again.

- To prevent foam from running or dripping from substrate, spray thinner passes.

- The foam expands more than the previous formulation, so spray faster passes. Initial spray does not need to be as thick to result in the same desired final thickness.

- Apply a flash-coat for optimal adhesion in suboptimal conditions (cool weather, difficult substrates). A fan nozzle is best used for this. Spray a very thin layer (~1/4” thick) on entire surface to be foamed. Allow the foam to become tack free (~1 minute). Then spray as usual to desired thickness.